|

:: Basic Comparison ::

| CHARACTERISTIC |

CAST

STEEL SHOTS |

OUR

|

| Raw Material |

Basic Raw Material has

far lower physical property & composition, obviously causes

blowholes & porosity which makes the shots to fracture into

small particle. |

Raw Material

is of exact composition without any material defect (blow holes,

porosity, shrinkage etc. ), and wears out nominally during it's

use. |

| Dust Generation |

Higher Dust generation |

No Dust generation |

| Environment Friendly |

Deteriorates environment

of work place and it's dust is considered hazardous to health |

Environment

Friendly |

| Performance Consistency |

Consistent Performance

not possible due to fast size deterioration |

Consistent

Performance |

| Time Consumption |

Higher consumption in

Shot Blasting/peening increases Working Cycle time |

Reduced Time

for Shot Blasting/Peening |

| Shot Consumption |

Higher

Consumption |

Consumption decreases i.e. 33% to 67% less to cast shots (case to case basis) |

| Inventory Cost |

Higher consumption requires

high Inventory, more money and Space as well |

Lower Inventory

required for the same job |

| Operation Cost |

Higher Operation Cost |

Lower Operation Cost |

| Shape Variations |

Shot being produced are

of mixed size hence product is a mix of various spherical sizes.

|

All shot being made out

of same wire are identical, no variation of size anywhere. |

| Hardness Variation |

They have larger variation

in hardness. |

Uniform hardness throughout |

| Micro-Structure |

In Micro-structure carbide

always there |

Micro-structure is only

Tempered martensite |

| Grain Size |

Grain size of cast

shot is unstabilized |

Due to drawing passes

grain size is stabilised |

::

Advantages ::

| CONSISTENCY |

BAPSHOT

exhibit highest consistency in size, shape, density &

hardness |

| DURABILITY |

BAPSHOT has

almost no internal defects (crack, porosity ,shrinkage

etc.), it's durability is many times as it maintains the

size longer and higher resistance. |

| NO

DUST GENERATION |

BAPSHOT do

not fracture into small particles so does not have any

dust generation. |

| LOWEST

SURFACE CONTAMINATION |

BAPSHOT leave

minimum residue on the parts surface and produces brighter

surface. |

| IMPROVE

PART FATIGUE RESISTANCE |

BAPSHOT (Conditioned)

when used for shot peening on parts, releases BAPSHOT

(Conditioned) when used for shot peening on parts, releases

|

:: Cost Savings ::

Due primarily to its superior Durability and Resistance to Fracture

as well as the absence of Iron Oxide coating, Cut Wire Shot provides

cost savings associated in Media Consumption, Dust Generated and removal

of Surface Contamination.

|

|

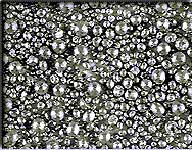

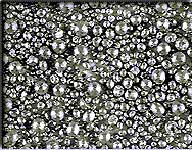

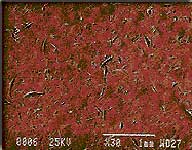

| Photo CCW35

- 1000 cycles |

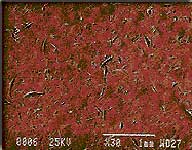

Photo CS330

- 1000 cycles |

Media Consumption - Durability testing can be done to measure representative

media life (in cycles) or breakdown rate (in grams per cycle). By

multiplying the breakdown rate (grams/cycle) by the cost of the media

($/gram), one can determine a relative cost per cycle ($/cycle)

| e.g.: |

CCW35 - Breakdown

Rate measured as 0.038 g/c, and

Cost = $0.00227/g.

Cost per cycle = 0.028 g/c x $0.00227/g=$0.000086/cycle.

CS330 - Breakdown Rate measured as 0.158 g/c, and

Cost = $0.000937/g

Cost per cycle = 0.158 g/c x $0.0009937/g=$0.000148/cycle. |

The

media consumption cost of CCW 35 is 58% that of the S-330 shot.

Dust Generation -

During Durability testing, and also during use, the Dust Generation

Rate (DGR) of a particular media can be determined. If 100 grams

of media is tested in a life Tester, a small amount of the sample

will exit the test machine as dust. The amount of dust lost divided

by the Number of cycles tested gives the DGR in grams per cycle

(g/c). Cut Wire Shot generates much less dust than other media,

and therefore cost of dust disposal can be reduced.

| e.g.: |

The cost in Cleveland,

Ohio to dispose of one 55 gallon drum

(containing 800 pounds of non-hazardous metal dust) is about

$55.00

or $0.000152/gram.

DGR of CCW35 = 0.0147 g/cycle

Cost of Dust Removal = 0.0147 g/c x $0.000152/g = $0.0000022/cycle

DGR of CS330 = 0.0254 g/cycle

Cost of Dust Removal = 0.0254 g/c x $0.000152/g = $0.0000039/cycle |

The

cost of dust removal of CCW 35 would be 56% that of the S-330 shot.

Surface Contamination -

Studies have shown that the residue left on the surface of a blasted

or peened part are much less (as much as 10 to 15 times less) with

cut wire shot compared to cast shot. On steel parts, the residue

(Iron Oxide) is not normally objectionable. But on non-ferrous parts,

it should be removed. Decontamination processes (chemical decontamination

is normally preferred) can be costly, dangerous to personnel, and

require disposal of spent chemical solutions. With surface residue

significantly reduced, decontamination time is also reduced. Exposure

of personnel to potential safety hazards is lessened and replacement

of spent chemical solutions is less frequent.

:: Detailed

Comparison ::

Improved Consistency -

Cut Wire Media exhibits the highest consistency from particle to

particle in size, shape, density, and hardness of any commonly used

metallic media.

Image Analysis was performed on various cast steel

media and equivalent conditioned cut wire (CCW) sizes. The variation

(Standard Deviation) in size of the cast shot shot was 1.5 times

that of the Cut Wire media. Image Analysis results of shape (roundness)

evaluation showed CCW media 2 times more consistent in shape than

equivalent cast shot sizes. Comparing hardness specifications -

cast shot normally meets an 11 point Rockwell C Hardness range (e.g.:

HRC 55-65, HRC 40-50, HRC 42-52) whereas CCW media ranges are normally

6 points or less (e.g.: HRC 55-60, HRC 50-55, HRC 56-59). The density

of Cut Wire Shot is the same as that of normal high carbon steel

- 7.8 grams/milliliter. Due to the large number of Internal Defects

may be present, specifications allow the density of cast shot to

be as low as 7.0 grams/milliliter - over 10% lower than Cut Wire

Media.

Highest Durability -

Because of its wrought internal structure with almost no internal

defects (cracks, porosity, shrinkage, etc.), the Durability (Life)

of CCW media can be many times that of cast shot of equivalent size

and hardness. Life testing in Laboratory and Production equipment

have measured the Life of CCW shot to be as much as 10 times that

of equivalent size and Hardness cast media.

In addition to the Durability of media, the mode of breakdown is

very important, especially in shot peening applications. Most media

deteriorates by forming broken (fractured) particles. CCW media's

mode of deterioration is wear. CCW particles tend to wear down into

smaller diameter pieces rather than fracture into sharp edge broken

particles.

|

|

| Surface Damage |

Fatigue Life

vs. % Broken Shot |

Dust Generation -

Since CCW media exhibits the highest Durability and Resistance to

Fracture, it also exhibits the lowest dust generation rate of the

commonly used media.

Lowest Surface Contamination -

All media leave a residue on the surface of the part being blasted

or shot peened. Those media that fracture rapidly can leave tiny broken

particles imbedded in the part surface. Other media leave a very thin

smear on the part surface. CCW media does not breakdown as quickly

as other media and does not tend to fracture into the tiny particles

that may imbed themselves into the part surface. Finally CCW media

does not have an Iron Oxide coating over the entire particle surface

which rubs off on the part being processed. Therefore CCW media leaves

much less (as much as 10 to 20 times less) residue on the part surface.

Improved Part Fatigue Resistance -

Fatigue tests have been performed on actual parts as well as laboratory

specimens to determine if one steel media is equal to, or better than,

another in terms of part life. Parts and specimens shot peened. with

CCW shot exhibit higher average life and more consistent life than

those peened. with equivalent cast steel shot.

|