Manufactured

from high quality wire, each particle is cut to a length about equal

to its diameter. If required, the particles are conditioned (rounded)

to remove the sharp corners produced during the cutting process.

Strict Quality Control procedures are required to be able to manufacture

cut wire shot meeting all common industry specifications as well

as many individual customer specifications.

|

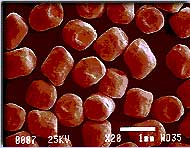

As-cut particles are an effective abrasive due to the sharp edges created

in the cutting process. However, as-cut shot is not a desirable

shot peening media. The sharp edges, which are potentially damaging

to fatigue life, must be removed in a process called "conditioning". |

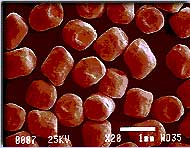

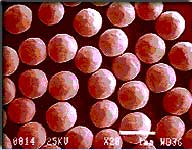

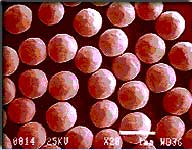

Conditioned Cut Wire (CCW) shot is normally

manufactured in two degrees of conditioning - Normal Conditioning

which meets the shape requirements of SAE J441 specification, and

the more rounded Special Conditioning which meets the requirements

of Aerospace specifications such as AMS 2431.

|

|

Normal ConditioningSAE

J441 |

Special ConditioningAMS 2431 |

Depending on application, various hardness

ranges are available with cut wire media. Generally, the higher the

hardness of the media, the lower the durability. However for shot

peening applications, the shot used should be at least as hard as

Almen strips or the part being peened, whichever is harder. Common

Hardness Ranges in Carbon Steel Cut Wire Shot are: Blasting Applications

- HRC 45-50; Shot Peening high strength parts such as carburized gears

and springs HRC 55-60; and Shot Peening softer parts - HRC 50-55.

Versatility - One

of the most important aspects of cut wire shot is its versatility.

Cut Wire Shot can be made from many materials: Stainless Steels

(Type 302, Type 304, Type 430 and others), 1070 Carbon steel of

various hardness levels, Aluminum, Zinc and Nickel alloys. Size

of media is not limited to the standards. Conditioning is offered

in Standard degrees: As-cut, Normal and Special. Other degrees of

Conditioning are, and can be supplied as well. Hardness ranges other

than those discussed above can also be supplied.

Source: Premier Shot Company,

Ohio, USA

|